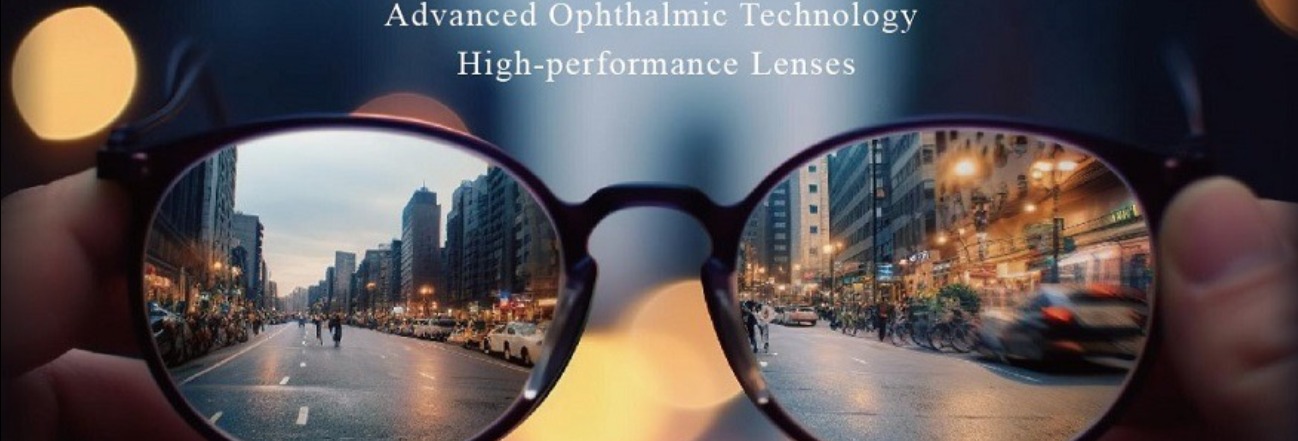

ABOUT DARWIN

Darwin optical established in 1997. The manufacturing plant is located in Taichung, Taiwan. Darwin offers a broad range of quality premium polycaronate lenses from single vision,bifocal,progressive,as well as Rx lenses with different designs and various treatments.With our extensive product offerings and commitment to quality,Darwin PC lens products are among the best in the optical industry.

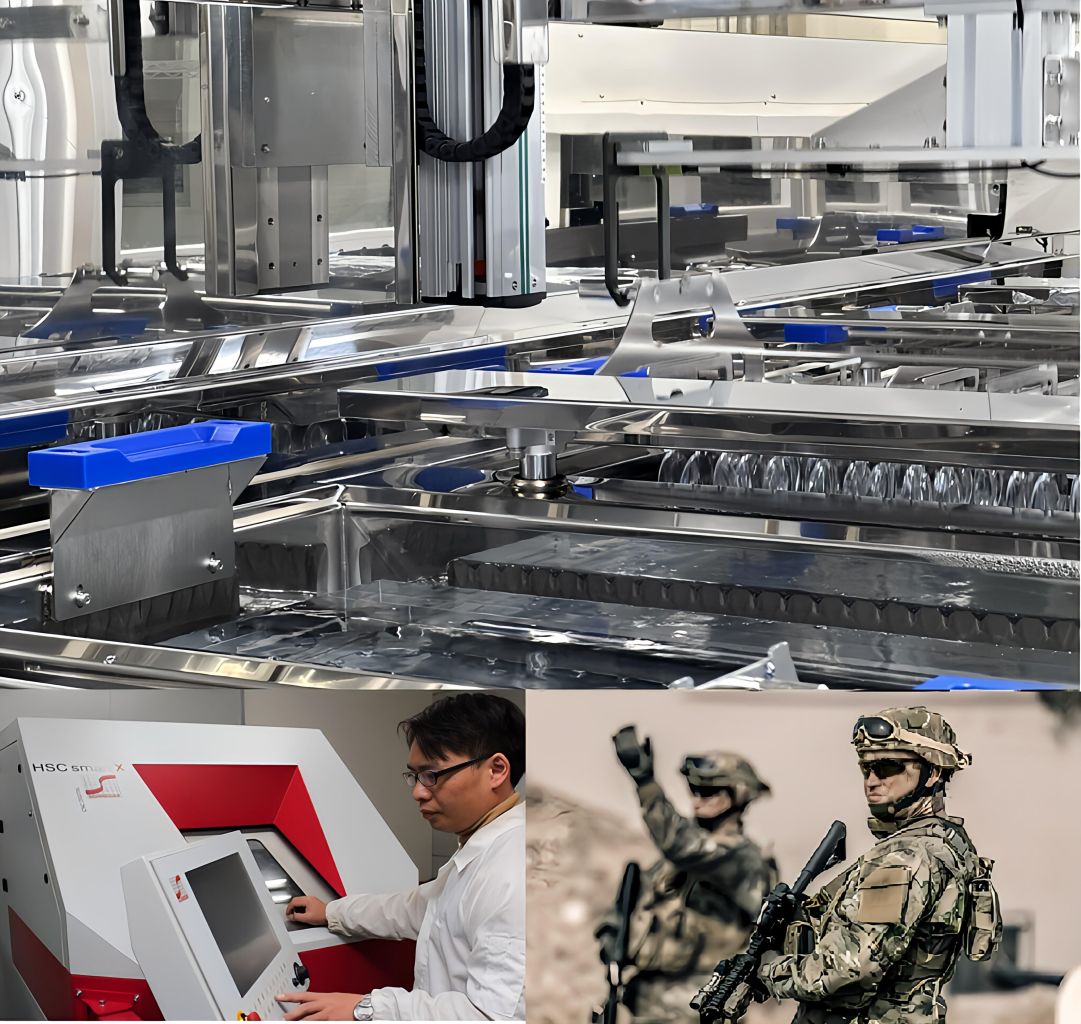

We are proud of being self-reliant in every stage of lens manufacturing process. Starting from the optical design of lenses,precision mold marking,injection molding to different coating process,each step is completed by skilled engineers and well-trained workers, maintaining the highest of standards and quality control. The self-molding manufacturing skills ensure better control on the lens' quality and provide more flexibility and efficiency during the production process.

Looking ahead, we will further intensify our R&D capabilities to uncover new polycarbonate technologies, materials and designs, and continue to introduce new products to enhance customer satisfaction and market competitiveness.

business philosophy

Pay attention to ophthalmic lens market changes and technology innovation for product. Towards to higher product quality and automated production efficiency. Darwin continues to pursue sustainable development and implement compliance with green environmental protection laws and regulations.

01

提升產品品質

Improve product quality

02

創新製程技術

Innovative manufacturing process

03

自動化生產效率

Automated production efficiency

04

企業永續發展

Corporate sustainability

History

| 1997 | Founded in Taichung, Taiwan |

| 1998 | R & D teams constructed a new factory and install production line |

|

2001

|

Introduce first pair of polycarbonate lenses to market |

| 2004 | Opened 2nd production factory in Taichung. Factory area is 5000m2 |

| 2006 | ISO 9001 certified and got japanese ministry of health and welfare certificate |

| 2007 | Launched 「Sunbalance 」Photochromic and 「Reach 」PAL products |

|

2008

|

「Sunbalance」Photochromic ophthalmic lenses was awarded “The 15th Taiwan SMES innovation Award” |

| 2009 | Extended 2nd. factory in Taichung. Launch polycarbonate finished Progressive lens. |

| 2011 | Obtain USA inventive patent in photochromic coating technology. |

| 2013 | Install RX LAB machine. Introduce BLITA blue light control 3C lens. |

|

2014

|

Introduce 「SUNBALANCE S6」 photochromic lens. |

| 2015 | A new factory is under construction. |

| 2016 | Introduce 「JAMORE 」high performance AR coating lens. |

| 2018 | Complete the 3rd factory |

| 2019 |

Introduce 「COSMIC」 PCUV420+ lens. |

| 2020 | Install lenses edging lab. Introduce「POLYTINT」Pre-tinted lens. |

|

2021

|

Introduce「FOGSKIP」anti-fog lens. Introduce「PolarART」polarized lens. |

| 2022 | Poly ophthalmic lenses export volume ranks first in Taiwan. |

complete product line

Finished Lens: Single vision、Bifocal、Progressive、Sphere and Aspherical design、AR/SAR、Tintable coating

Semi-Finished Lens: 70/75/80mm

Featured Lens: Photochromic lens、Polarized lens、Pre-tinted lens、UV420 lens、photochromic UV420 lens、Anti-fog lens、Super hydrophobic lens、High contrast lens、Amblyopia/color blindness lens 、Photochromic goggle、Photochromic sunlens

R & D capabilities

Darwin R&D team has created a number of firsts in the past 20 years.

Darwin is the first company to successfully develop and mass-produce ophthalmic PC lense with domestic technology in Taiwan.

The photochromic lens developed in 2008 is the first in fading speed.

The photochromic anti-fog goggle developed in 2011. It is the first anti-fog specification that can pass N 、 K and also pass the impact resistance test of the U.S. military standard.

Darwin is the first company that has successfully developed a long-lasting PC anti-fog ophthalmic lens (non-maintenance type) in 2016

Advanced PC ophthalmic lens production technology requires the integration of multiple technologies, such as:

- Material science

- Optometry

- Optical lens design

- Injection molding

- Thin film deposition

- Hard coating

- Mold & insert development and design

Manufacturing capacity

製程提升

Process improvement

Strong ability to develop and improve the processes by ourselves. Continuously improve quality and launch new products.

品質保證

Quality Assurance

100% of the lenses have been inspection by quality assurance personnel. It can ensure that there are no defects in the quality of the products.

生產迅速

fast production

With the flexible and lean production model, the optimal production schedule can be adjusted in a short period of time, more output can be scheduled, inventory manangement can be optimized. These can meet our clients' diverse needs.